A newly patented surface moves drops along certain paths - all it takes is a shake.

The simple technology is a textured surface that tends to push drops along a given path. It's inspired by the lotus effect – a phenomenon in which a lotus leaf's almost fractal texture makes it appear to repel drops of water. They used nanotechnology manufacturing techniques to build a surface with tiny posts of varying height and spacing. When a drop sits on this surface, it makes so little contact with the surface that it's almost perfectly round. That means even a small jiggle can move it. Then they used an audio speaker to vibrate the platform at 50 to 80 times per second. The asymmetrical surface moves individual drops along predetermined paths to mix, modify or measure their contents. Changing the vibration frequency can alter a drop's speed, or can target a drop of a certain size or weight.

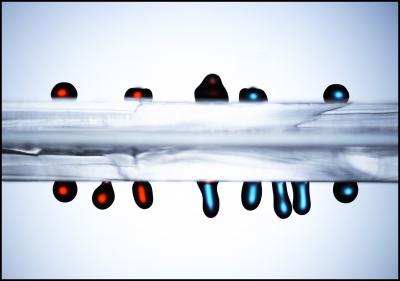

Drops of red and blue liquid move along the upper and lower surface of the vibrating UW platform at speeds up to 1 inch per second. This combined image shows drops as they move toward the center and merge. Credit: Karl Bohringer, UW

"The lotus leaf has a very rough surface, in which each big bump has a smaller bump on it," said Karl Böhringer, a professor of electrical engineering and bioengineering at the University of Washington. "We can't make our surface exactly the same as a lotus leaf, but what we did is extract the essence of why it works. All you need is a vibration, and making these surfaces is very easy. You can make it out of a piece of plastic. I could imagine this as a device that costs less than a dollar – maybe much less than that – and is used with saliva or blood or water samples."

In testing, different versions of the UW system could move the drops uphill, downhill, in circles, upside down, or join two drops and then move the combined sample.

The type of system is known as a "lab in a drop" - all the ingredients are inside the drop, and surface tension acts as the container to keep everything together.

A student tried using a smartphone's speaker to vibrate the platform, but so far a phone does not supply enough energy to move the drops. To better accommodate low-energy audio waves, the group will use the UW's electron beam lithography machine to build a surface with posts up to 100 times smaller.

"There's good evidence, from what we've done so far, that if we make everything smaller then we will need less energy to achieve the same effect," Böhringer said. "We envision a device that you plug into your phone, it's powered by the battery of the phone, an app generates the right type of audio vibrations, and you run your experiment."

Published in Advanced Materials. Co-authors of the paper are former UW undergraduate Todd Duncombe and former UW graduate student Yegȃn Erdem, both at the University of California, Berkeley; former UW postdoctoral researcher Ashutosh Shastry, now at Corium International in Menlo Park, Calif.; and Rajashree Baskaran, a UW affiliate assistant professor of electrical engineering who works at Intel Corp.

Comments