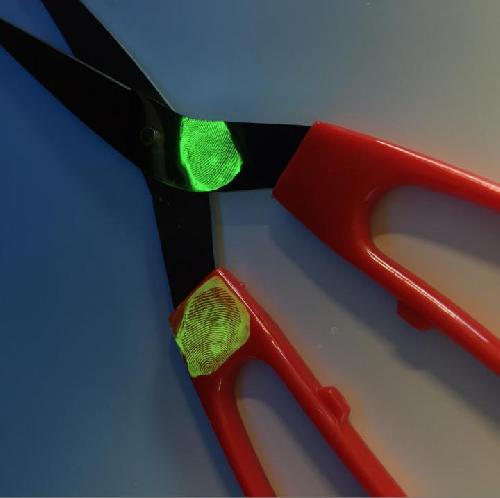

A new crime scene identification technique for fingerprint detection and analysis adds a drop of liquid containing crystals to surfaces, which means investigators using a UV light are able to see invisible fingerprints "glow" in about 30 seconds.

The strong luminescent effect creates greater contrast between the latent print and surface enabling higher resolution images to be taken for easier and more precise analyses.

CSIRO materials scientist Dr Kang Liang believes that this technique could be used for more challenging evidence where conventional 'dusting' is not appropriate.

"While police and forensics experts use a range of different techniques, sometimes in complex cases evidence needs to be sent off to a lab where heat and vacuum treatment is applied," Dr Liang said.

"Our method reduces these steps, and because it's done on the spot, a digital device could be used at the scene to capture images of the glowing prints to run through the database in real time."

CSIRO's study shows that tiny crystals rapidly bind to fingerprint residue, including proteins, peptides, fatty acids and salts, creating an ultrathin coating that's an exact replica of the pattern.

"Because it works at a molecular level it's very precise and lowers the risk of damaging the print," Dr Liang said.

CSIRO tested the method on nonporous surfaces including window and wine glass, metal blades and plastic light switches, with successful results.

Fingerprint identification has been used as a key method by law enforcement and forensic experts for over 100 years. Adding CSIRO's method to the mix could save valuable time, costs and enhance investigations.

"When my house was broken into I saw how common practice fingerprinting is for police," Dr Liang said.

"Knowing that dusting has been around for a long time, I was inspired to see how new innovative materials could be applied to create even better results.

"As far as we know, it's the first time that these extremely porous metal organic framework (MOF) crystals have been researched for forensics."

MOF crystals have a number of benefits in that they are cheap, react quickly and can emit a bright light. The technique doesn't create any dust or fumes, reducing waste and risk of inhalation.

Comments