As the global demand for air travel increases, so too does the demand to decrease the environmental impact of flight. The answer may lie in the technological advances made by the next generation of short-haul commercial aircraft currently in development by British low-cost airline, EasyJet. The unique design of EasyJet’s “EcoJet” promises a 50% reduction in CO2 emissions by 2015.

The aircraft will incorporate the latest research by airframe and engine manufacturers around the world – all of which can be incorporated into an aircraft that should be in operation by 2015. The projection for the 50% CO2 reduction is based on the findings from the latest research by industry leaders and will come from the engines (25%), the lightweight airframe (15%) and from improvements to air traffic control technology and design (10%).

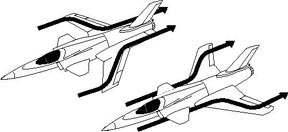

One of the key design changes made in the EcoJet, is the use of rear-mounted “open-rotor” engines. The reason behind this is simple physics. The environmental performance (fuel efficiency) of a modern jet engine is related to the mass of air that the fan can move, which is driven by the rotor diameter of the fan blades - the larger the fan, the greater the propulsive efficiency. Conversely, containing such a large diameter fan in a casing would have significant weight and drag penalties. In the short-haul sector of the market, unducted fan (open rotor) engines offer unrivalled environmental performance due to their higher propulsive efficiency. However, there are significant design penalties in fixing such a large engine under a wing of such a small aircraft, making rear mounting of the engines the optimum solution.

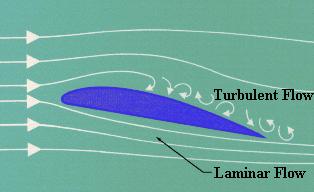

The EcoJet also employs an efficient forward-swept wing design. One of the primary methods of reducing fuel burn is by reducing drag. Conventional jet aircraft currently suffer increased drag from turbulent airflow over their wings.

A forward swept wing however, enables airflow from wing tip to wing root; and a wing profile that provides laminar flow over a significant proportion of the wing.

Laminar flow is the smooth, uninterrupted flow of air over a wing, and is essential to lift. When the smooth flow of air is interrupted over a wing section, turbulence is created which results in a loss of lift and a high degree of drag. The EcoJet’s use of a forward-swept configuration will prolong laminar flow and greatly reduce drag during cruising speeds.

The requirements of a laminar flow wing will dictate a slightly slower design cruise speed – Mach 0.75 (570.9 mph, 918.8 km/h) compared to Mach 0.78/0.79 for today’s conventional designs. On the average short haul sector this would add 3-10 minutes to the flight, but it is anticipated that air traffic control improvements and faster turn-around times on the ground will compensate for this increase in flight time.

The EcoJet will have at least 3 full size doors, allowing airlines to board passengers through all three doors, speeding up turn-around times. Even boarding from a single jetbridge connected to the central pair of doors will speed up boarding times, as passengers would be able to head either up or down the aircraft upon entrance instead of forming a single line once inside. The EcoJet will also be a more autonomous aircraft, requiring less ground equipment -- e.g. as the fuselage is closer to the ground, a belt loader will not needed for the bulk loading and unloading of baggage.

The current average trip length in the short-haul market is around 500 nautical miles (575 miles, 926 km) and 98% of all commercial flights in the 120-240 seat segment are below 2,000 nautical miles (2,302 miles, 3,704 km). Therefore the design range of the EcoJet will be 2,000 nm or less. This reduction of the design range will reduce the weight and size of the aircraft, and will therefore further increase its fuel efficiency.

Additional weight reductions will be realized through the use of advanced weight-reducing materials similar to those used in current projects like the Boeing 787 -- which itself is estimated to be 27% more fuel efficient than the aircraft it will replace in many fleets. The wings of the EcoJet are to be manufactured out of carbon fiber composites.

The EcoJet will provide 150-250 seats in single class configuration, and 130-220 seats in a 2-class offering. In easyJet’s current configuration and operation, the projection for the eco-liner would generate less than 47g of CO2 per passenger km (0.167 lb/passenger mile). For comparison, EasyJet’s current operations generate 97.5g of CO2 per passenger km (0.346 lb/passenger mile), the Toyota Prius emits 104g of CO2 per kilometer (0.369 lb/mi); and the European car industry has recently been given a target to achieve 130g of CO2 per kilometer (0.461 lb/mi).

Speaking at a press conference to unveil the EcoJet, Andy Harrison, EasyJet Chief Executive, said:

“The aviation industry has an excellent record in reducing the environmental footprint of aircraft. Today’s aircraft are typically 70% cleaner and 75% quieter than their 1960s counterparts. Now we are planning the next generation that will help towards taking the plane out of the emissions equation.”

“The EcoJet represents the next major step forward in airframe and engine technology. The lightweight structure and open-rotor engines are based on technologies that are being developed right now by the major manufacturers. The ‘EasyJet EcoJet’ is realistic and it is achievable.”

More on EasyJet's EcoJet

Comments