If we aren't getting improvements over 1980s lithium-ion batteries any time soon, at least they can be optimized, and a recent study introduces a knee point prediction method based on neural networks. Understanding battery life and capacity degradation at each stage allows companies to better detect the knee point - where degradation occurs sharply. This will enable predictive maintenance and prevent the occurrence of failures until modern batteries come into existence.

Capacity degradation analysis and knee point prediction for lithium-ion batteries. Credit: Green Energy and Intelligent Transportation

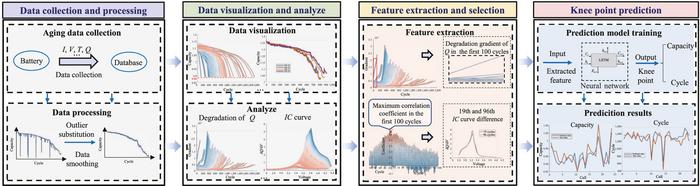

The framework uses data acquisition and processing, battery data visualization and analysis, feature extraction and selection, and capacity knee point prediction. The stated battery cycle aging data plus voltage, current and capacity are preprocessed. Then the mechanism of battery capacity degradation is analyzed based on capacity degradation gradient and incremental capacity (IC). The feature sets are composed of the capacity degradation gradient and the difference of the maximum correlation IC curve. The target features are taken as inputs while the corresponding capacity and cycle are taken as outputs to 'train' the network. Finally, the knee point of capacity degradation is predicted by using the trained prediction network and extracted features.

The degradation mechanism of the batteries are analyzed using longitudinal and horizontal contents. The former is concentrated in whole cycle life degradation. The latter is analyzed from the charge–discharge protocol and internal materials. Understanding degradation mechanisms helps improve charging and discharging strategies, maximizing battery lifespan and efficiency.

Their prediction method performed better than other benchmark methods in predicting knee point's capacity and cycle synthetically. The average mean relative error (MRE) of the capacity and cycle of the proposed LSTM method are 0.68% and 9.64%, respectively.

Comments