The COVID-19 pandemic has led to rampant new use of personal protective equipment (PPE) but we're also facing a problem of more garbage in landfills. It could be trivial but in a world where people people about Keurig K-cups, technology to turn billions of items of disposable PPE from its polypropylene (plastic) state into biofuels mean it can be a viable consideration.

A study in Biofuels explains that the transformation into biocrude, a type of synthetic fuel, will not just prevent the severe after-effects to humankind and the environment but also produce a source of energy.

"There is a high production and utilization of PPE to protect the community of health workers and other frontline workers of COVID-19. The disposal of PPE is a concern owing to its material i.e. non-woven polypropylene," says lead author Dr Sapna Jain. "The proposed strategy is a suggestive measure addressing the anticipated problem of disposal of PPE."

During the current COVID-19 pandemic specifically, PPE is being designed for single use followed by disposal. Once these plastic materials are discharged into the environment they end up in landfill or oceans, as their natural degradation is difficult at ambient temperature. They need decades to decompose. Recycling these polymers requires both physical methods and chemical methods. Reduction, reuse and recycling are the three pillars of sustainable development that can help to prevent the disposal of plastic to the environment.

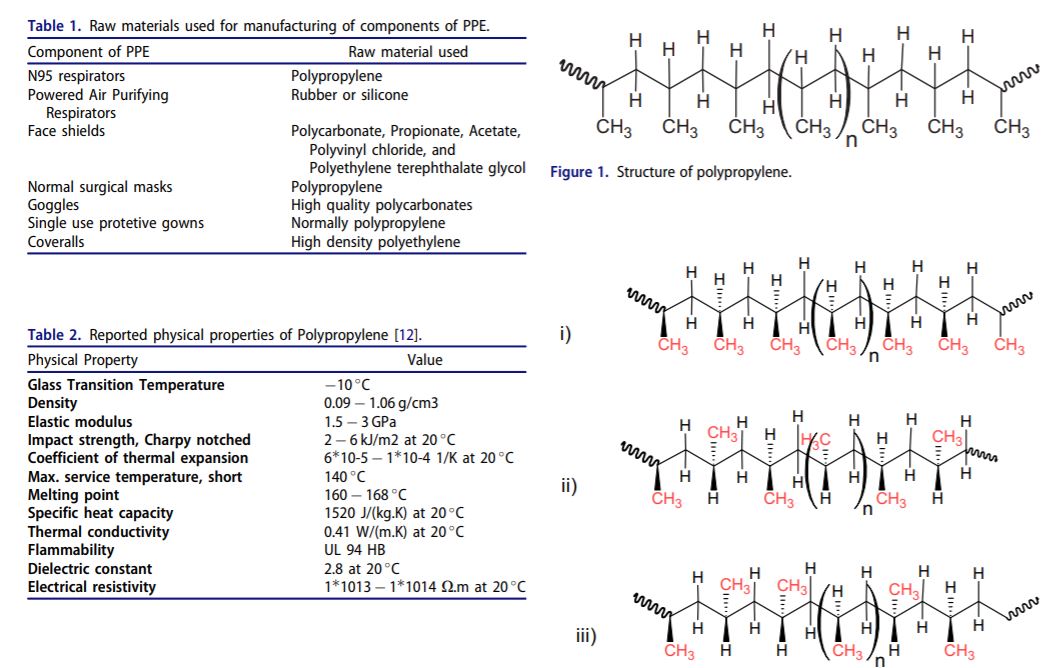

The research team reviewed many related research articles as they looked to explore the current policies around PPE disposal, the polypropylene content in PPE, and the feasibility of converting PPE into biofuel.

In particular, they focused on the structure of polypropylene, its suitability for PPE, why it poses an environmental threat and methods of recycling this polymer.

Their conclusive findings call for the PPE waste to be converted into fuel using pyrolysis. This a chemical process for breaking down plastic at high temperature - between 300-400 degree centigrade for an hour - without oxygen.

Co-author Dr Bhawna Yadav Lamba says this process is among the most promising and sustainable methods of recycling compared with incineration and landfill. "Pyrolysis is the most commonly used chemical method whose benefits include the ability to produce high quantities of bio-oil which is easily biodegradable," she states. "There is always a need for alternative fuels or energy resources to meet our energy demands. The pyrolysis of plastics is one of the methods to mitigate our energy crisis.

"The challenges of PPE waste management and increasing energy demand could be addressed simultaneously by the production of liquid fuel from PPE kits. The liquid fuel produced from plastics is clean and have fuel properties similar to fossil fuels."

Comments