Varnish does more than just provide a protective sheen to a violin. It influences the vibrations and impulses that the wood absorbs and therefore the quality of sound the instrument produces, says Marjan Gilani of the Swiss Federal Laboratories for Material Science and Technology (EMPA) in Switzerland. In research published in Springer's journal Applied Physics A, Gilani and her colleagues demonstrate the importance of the vibro-mechanical properties of varnish, its chemical composition, thickness and penetration into wood.

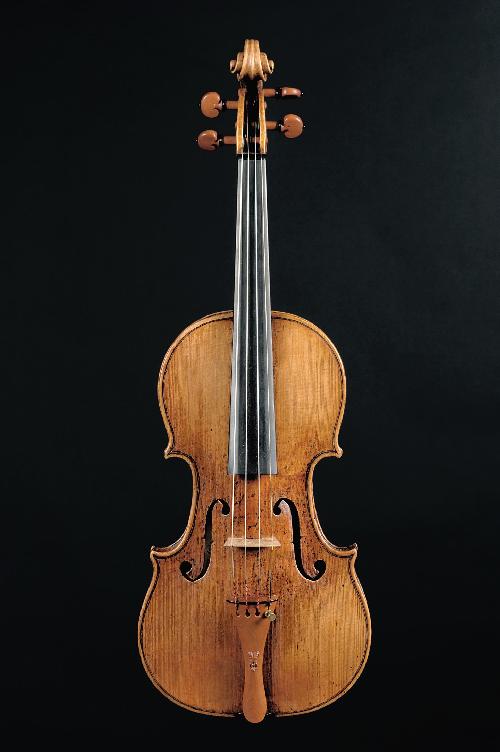

Often, a violin's sound board is made of spruce tonewood. Varnish is applied to protect the wood from the long-term effects of humidity and wear. Violin makers normally have their own particular method for applying varnish to finished instruments. It is applied in liquid form, and then dries to a solid transparent film.

Gilani's team investigated how the hardening effect of varnish changes the vibrational properties of master grade tonewood specimens when using four different varnishes. The researchers prepared two simple varnish recipes themselves, and obtained two other varnishes from German master violin makers. These were applied on specimens of Norway spruce tonewood cut from the outer and inner part of the same tree.

Non-destructive methods such as vibration tests and X-ray tomography techniques were used to take measurements before and after coating with the various varnishes, and at different stages of hardening. The thickness of the varnish and the depth to which it penetrates into the wood were among the features measured. The researchers carefully noted how the microstructure and physical properties of each varnish influences the wood's natural frequencies and internal damping. The latter refers to a material's ability to absorb and stop vibrations quite rapidly.

It was found that all the varnishes increased damping throughout the wood surface. A moderate increase of damping can, in general, benefit the sound of violins. When high notes are dampened, instruments sound warmer and more mellow. In unvarnished wood, the sound is faster along the grain and slower perpendicular to it. The sound is also damped more strongly perpendicular to the grain than along the grain. With all applied varnishes, these differences are reduced, leading to a more isotropic* sound radiation. The varnishes of the German violin makers reduced these differences even more than the laboratory varnishes. Additionally, their varnishes also allowed for a higher sound radiation than the laboratory varnishes, thus leading to a louder tone to be emitted.

"Varnish coating plays an important role for the long-term quality of the sound of wooden musical instruments, but as applied on the wood surface, impulse changes in the vibro-mechanical behaviour of wood can be recorded," says Gilani.

Comments